Introduction

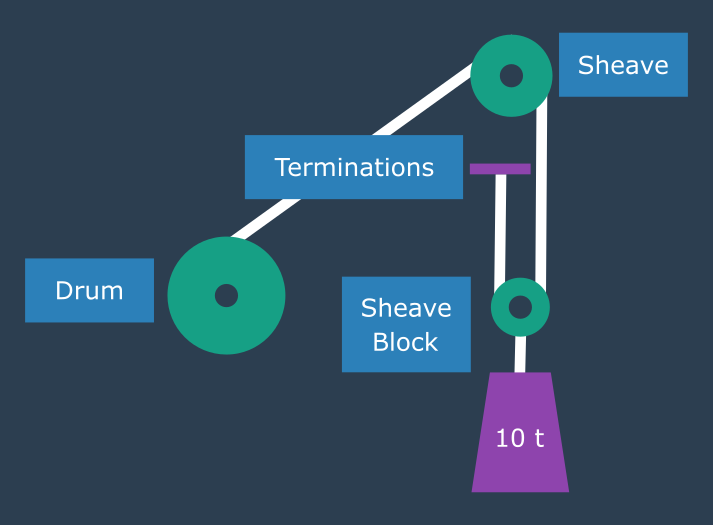

Fatigue wire breaks are the natural end-state of a working wire rope. Bending, twisting, stretching, or vibrating the wires too many times will result in breaks. Wire rope is often retired before this happens, but in the instances where it occurs, certain sections of the rope are more likely to be subject to fatigue than others.

Where does fatigue occur?

Fatigue can occur in any section of wire rope. However, it is more likely in the following sections:

Fatigue can occur anywhere in wire rope but is usually isolated to a specific locations within the reeving arrangement.

1. The working part of the wire rope

Of all the likely places where fatigue may occur, the main working part of the rope is the most common, particularly where there is contact with the sheaves. Where the working part of the length is relatively long, the fatigue breaks will be randomly scattered along this length. If the length is relatively short, the concentration and likelihood of fatigue breaks will be greater as a shorter length of rope is doing all the work. If the sheave (D:d ratio) diameter is small - less than 20 times the rope diameter - fatigue will increase exponentially.

2. Next to the termination

Pulsatory fatigue can cause wire breaks next to the termination, particularly when the termination is heavy. Pulsatory fatigue is common in grabbing operations.

3. Drum

As the wire rope spools on and off the drum it will be subject to bending fatigue. As with sheaves, a small D:d ratio will increase fatigue breaks exponentially.

4. Compensating or equalising sheave

The wire rope immediately adjacent to this sheave on some designs of overhead traveling cranes is a danger zone for fatigue breaks as only a small length of the wire rope is being used to offset small differences in rope payout on a double drum. These will be difficult to find as they will be on the underside of the wire rope in contact with the sheave and the wire rope will need to be lifted off or moved away from the sheave to view any broken wires.

Fatigue breaks where they indicate a sheave problem

1. Sheave is too tight

A telltale sign of this on the wire rope is two lines of broken wires running down the rope coinciding with the pinch point between the sheave contact point and the wire rope.

Diagram illustrating a tight sheave.

2. Sheave is oversized

The wire rope will not be supported suitably, and over time, the rope will flatten. Fatigue will manifest as a single line of broken wires.

Diagram illustrating an oversized sheave.

Fatigue breaks can occur even in an unloaded wire rope!

If a crane is parked up and the crane block is not secured the wire rope can move over the top sheave due to wind or in the case of offshore or ship cranes - wave movement. As the movement is very localised, this can quickly lead to fatigue breaks!

The Rope IQ team.

Want to find out how our software can help your business?

Request a quick 30 minute demo to find out.

Request a Demo